Zimmerman, MN (April 19, 2021)…

As a manufacturer of implantable medical devices and tight-tolerance precision machined components, quality assurance (QA) is an essential part of UMA Precision Machining’s production cycle. Equally important is ensuring that the Company’s quality standards and associated documentation do not sacrifice timely delivery to customers.

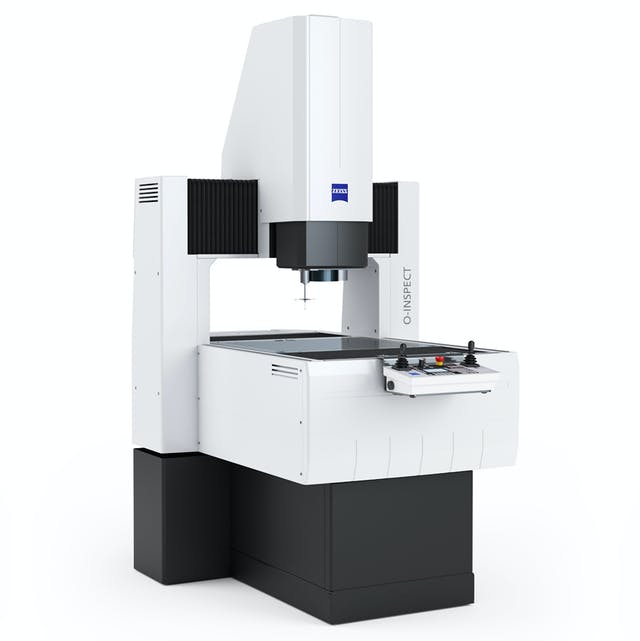

UMA Precision Machining has purchased a Zeiss O-Inspect Multisensor Measurement System to meet this need for assured gauging accuracy and efficient production. The O-INSPECT combines optical and contact measuring technology in one system, allowing the user to aggregate additional data points and reduce inspection time. Its accompanying software also offers one-click reporting to automatically document and visualize measurement data. This recent addition is part of UMA Precision Machining’s ongoing commitment to quality and customer service.

“Adding the Zeiss O-Inspect gauging capabilities to UMA Precision Machining’s quality system will ensure the most demanding requirements are accurately evaluated,” states Travis Dommer, Quality Manager of UMA Precision Machining.